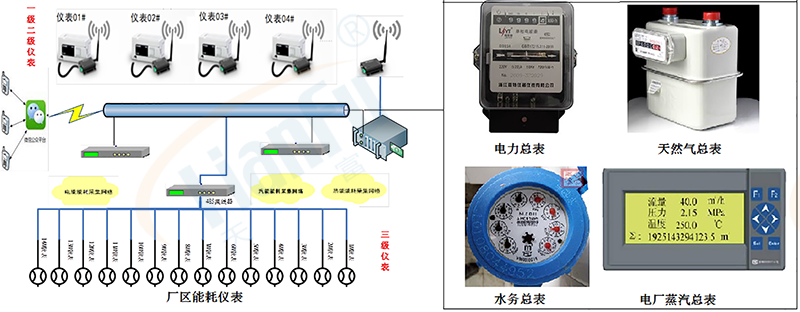

1. Automatic acquisition: Including external master meter, establishing three-level energy acquisition system of enterprises, automatically changing shifts every day, automatic timeliness meter reading, saving time and labor, report data more accurate and reliable, in order to achieve effective energy cost accounting.

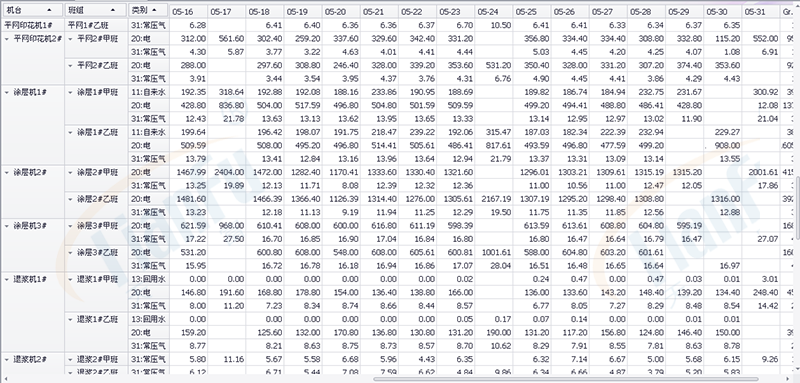

2. Combine with ERP: Establish a set of unit energy consumption assessment system for the team, through the ranking of energy consumption cost in each process and the ranking of energy consumption reduction rate in each group, in order to stimulate the enthusiasm of employees to save energy and realize the ideological change from passive energy to active energy

3. The equipment with low energy consumption efficiency can be found and maintained in time to avoid unnecessary waste of energy consumption and improve the service life of the equipment.

4. The total error of the total table and the sub-table can discover the "leak" of energy consumption in time, and establish a set of energy consumption diagnosis system for production to reduce energy consumption.

5. Optimizing the process: find out the high energy consumption of different cloth and process in time, find out the weak link of the process and then optimize it. Combining with ERP, the energy consumption analysis of each order or different cloth can be realized, which is beneficial to the business analysis.

1. Make full use of the existing LAN, wired and wireless combination, using different methods, all energy instruments have methods to access the system, to achieve centralized and unified screen monitoring, investment is rare and quick.

2. Connect with the factory ERP output, statistics to the A-E-C team, combined with machine output, truly realize the assessment function, not just a meter reading system.

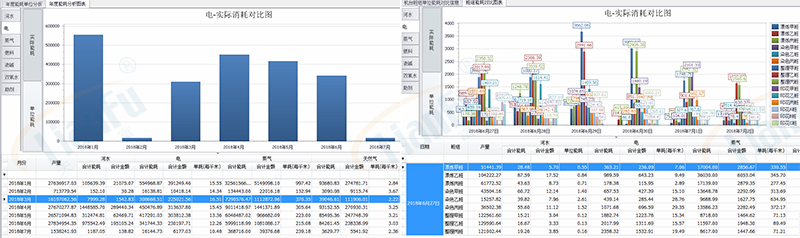

3. Intelligent Energy Consumption Analysis: Longitudinal and transverse analysis of energy consumption data in different workshops and different time periods to find waste points and save energy consumption space.

4. Limit-crossing alert: Users can set alert according to their own wishes, and the alarm is summed up in different alarm windows, according to different alarm levels, the sound, screen and other different prompts.

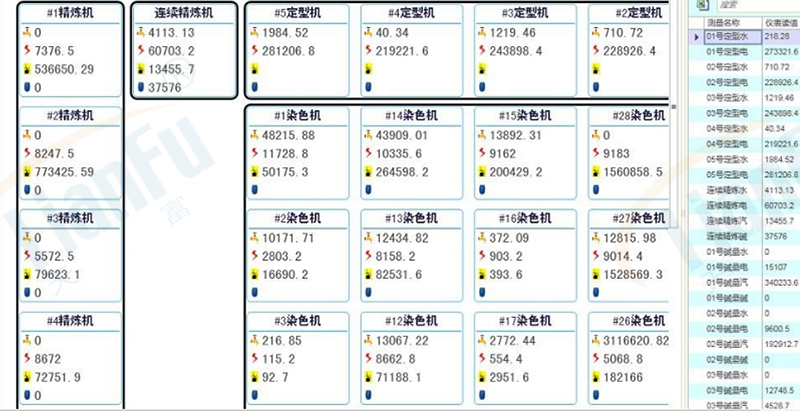

5. Energy consumption monitoring of key equipment: monitoring of key energy-using equipment, specific electricity consumption, active and reactive power, voltage and current, instantaneous, cumulative consumption, energy curve trend.

6. It can be docked with the existing ERP system of the factory to calculate the energy consumption cost of orders and varieties, and guide the business quotation.

Energy consumption monitoring of key equipment

Comparison of energy consumption between teams and groups

Monthly energy consumption comparison