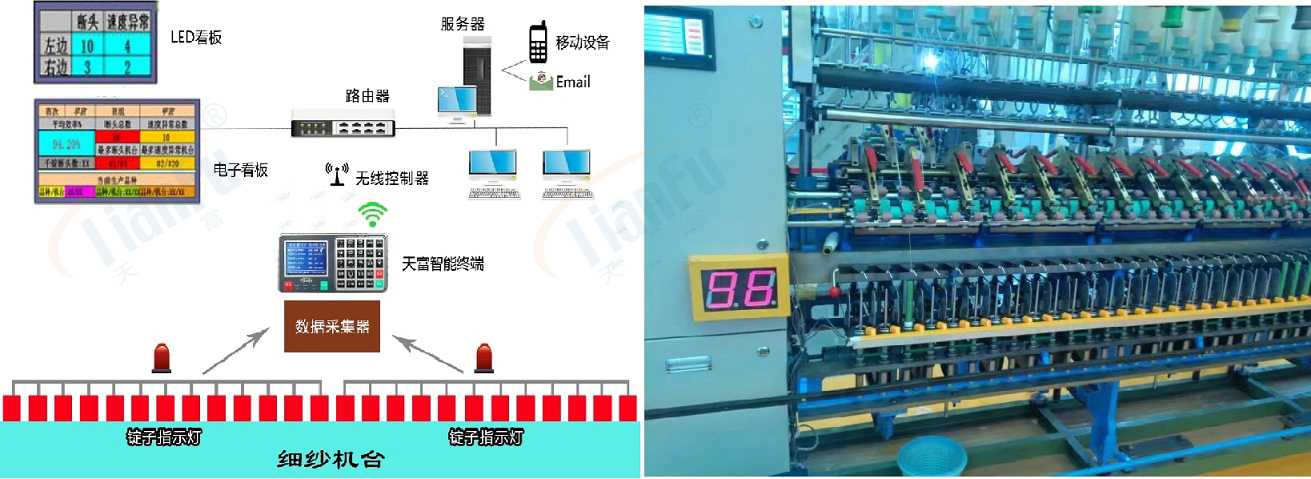

system configuration

1. Each spindle is equipped with a spindle detector and a red display lamp. The red light flickers at the broken end of the yarn, and the speed is unusually long and bright;

2. Each spinning frame is made up of multiple single spindle devices, each with a data collector and an intelligent terminal;

3. Intelligent terminal is connected with data acquisition device, and the collected data is transmitted to the back-end server by means of Zigbee;

4. Install LED and red light green light on the head of each machine. According to the specific break and speed anomaly with different light combination display; LED display the current left break, speed anomaly, right break, speed anomaly number。

System Effectiveness

1. It can detect broken ends, strong and weak twists, bad spindles (backward spindles), idle spindles. It has the functions of breaking ends analysis in 1000 spindles, breaking ends analysis in yarn dropping, joint time analysis and so on;

2. It does not affect the operation of the original spinning joint, and has no harmful influence on the yarn quality, ring and traveler operation; the monitoring signal means are environmental protection and no interference;

3. The yarn quality and personnel efficiency have been significantly improved. With intelligent lighting and other equipment, it can also realize black light factory, reduce roving waste and save raw material costs;

4. Promotion of management level: the intensity and effect of workers'work is clear at a glance, thus avoiding the shirking responsibility among different types of work. And training for new employees is easier.