At present, many textile printing and dyeing enterprises in the cloth inspection and winding packaging process there is a low operating rate of the situation:

1. It is a heavy and error-prone link to fill in labels manually, to write a large number of repeated information, and to convert meter codes.;

2. Manual calculation of cloth damage, short/multi-code, transcribing code sheet, unclear handwriting, error is difficult to avoid;

3. It is difficult to know the execution progress and wastage status of the order in time because special statisticians are required to statistically distribute the report forms and related data afterwards;

4. The historical data can only be saved by paper documents. It is difficult to query the historical data and it is difficult to retrospect the quality;

5. In some cases, the results of inspection are often not recognized by the cloth manufacturer, resulting in many cloth manufacturer to ask the cloth inspector to re-examine the cloth;

6. In addition, the lack of data statistics ability can not achieve effective quality management purposes.

1. Tianfu cloth testing the packaging system to adapt to the characteristics of high temperature, dust, static electricity and vibration.;

2. Connecting with the code list and weighing instrument of mainstream communication in the market, you can choose Tianfu brand's communication code table.;

3. Labels, code sheets, and defect report formats can be defined flexibly;

4. Stainless steel, multi-directional pushing and rotating support, suitable for installation of various inspection machines (flat inspection, vertical inspection);

5. Support for cloth cutting, matching, filling and other functions;

6. It supports handwriting input, and handwriters can directly hand write comments and comments on the scene;

7 Provide a standard data interface for third-party calls, combined with PDA scanning bar code docking ERP inventory system smoothly.

(1)Inspection site photos

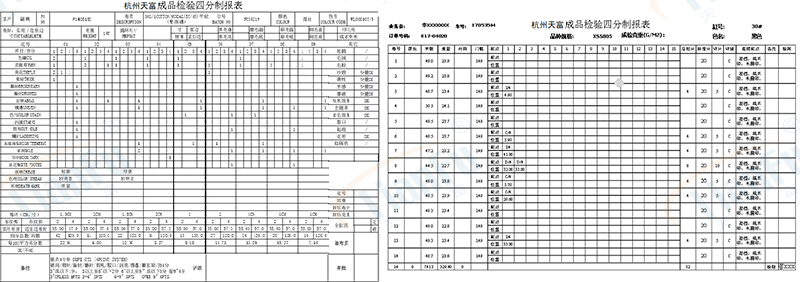

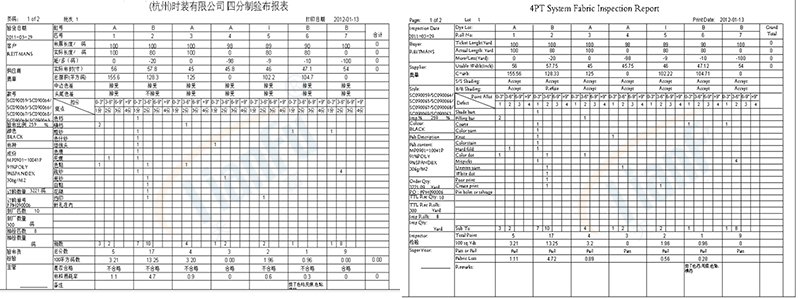

(2)Four sub report

(3)Barcode Label

(4)Inspection analysis report and on-site Kanban