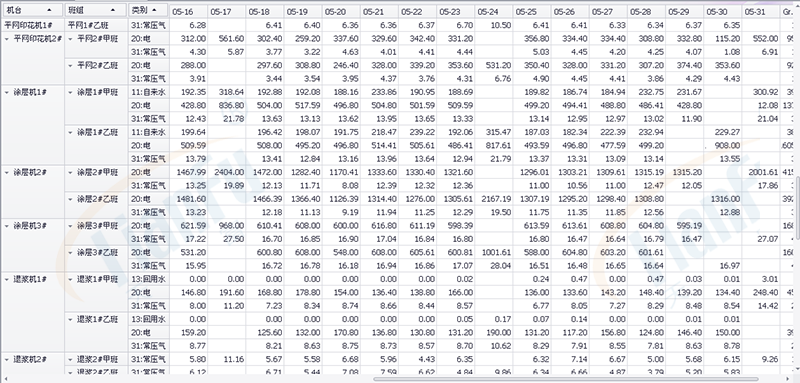

2. Connecting with the ERP output of the factory, counting to the A-E-C group, combining with the output of the machine, we can really realize the assessment function, not just a meter reading system;

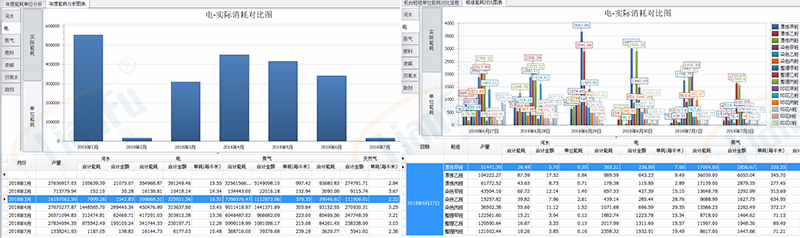

3. intelligent analysis of energy consumption: vertical and horizontal analysis of energy consumption data of different workshops and different time periods to find out waste points and save energy consumption space;

4. alert warning: users can set up their vigilance according to their own wishes, and induce the alarm in different alarm windows. According to different alarm levels, different hints of sound, picture and so on are introduced;

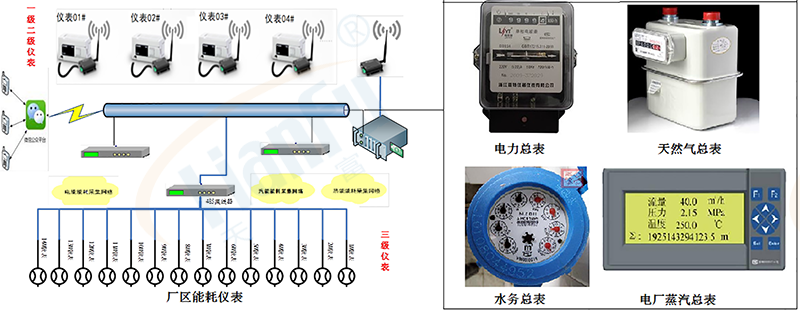

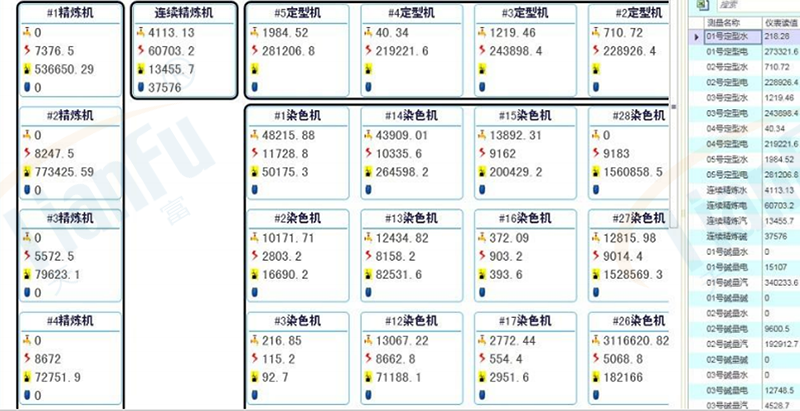

5. energy monitoring of key equipment: monitoring the key energy use equipment, specific electricity consumption, active and reactive power, voltage and current, instantaneous, accumulative amount, energy curve trend;

6. it can connect with the existing ERP system of the factory, calculate the energy consumption cost of orders and varieties, and guide the quotation of business quotations.